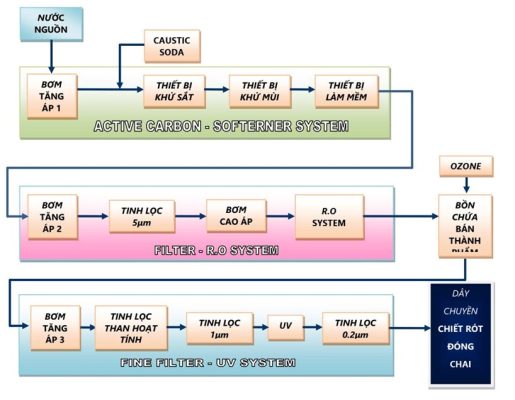

To provide clean and healthy drinking water for students and faculty members, Nguyen Tat Thanh University has invested in on-site water extraction systems. These water extraction systems ensure a safe and reliable supply of drinking water for the entire university. Additionally, the university has set up free drinking water stations that utilize purified water produced by the university itself. This not only allows students to access free drinking water but also helps reduce plastic bottle waste in the environment.The bottled water production line consists of four treatment systems. These include the coarse treatment system, the RO filtration system, the disinfection and sterilization system, and the bottling system. The basic operation process of the bottled water production line includes the following steps:

- Pre-treatment stage: This stage involves removing metals, eliminating odors, and softening the water according to standards.

- RO filtration: The water goes through an RO membrane to remove 100% of toxins, bacteria, and viruses, resulting in pure and safe water that meets the health standards set by the Ministry of Health.

- Disinfection and sterilization: This step helps prevent bacterial recontamination and ensures the water is fresh and odorless.

- Bottling and capping: The bottling system is designed with three stages: cleaning, bottling, and capping.

RO WATER FILTRATION PROCESS DIAGRAM

Production room for beverages at 298A Nguyen Tat Thanh

Free drinking water station at 300A Nguyen Tat Thanh

Free drinking water station at 300A Nguyen Tat Thanh

Free drinking water is provided for staff and visitors at the campus.

Cutting the ribbon to inaugurate the free direct drinking water filtration system donated to District 12 Hospital.

1900 2039 – Ext: 408

1900 2039 – Ext: 408 thuvienntt@ntt.edu.vn

thuvienntt@ntt.edu.vn